Material Respectful

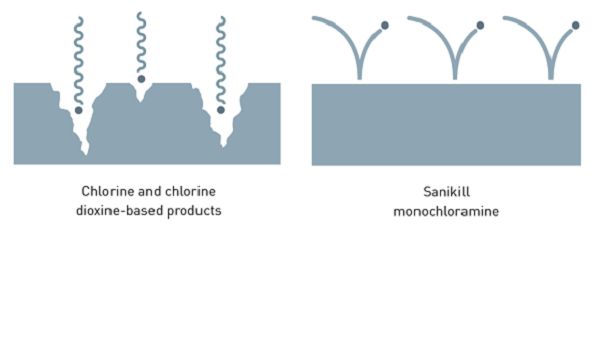

Pipe corrosion and disinfection are usually linked, but not with SANIKILL, that uses monochloramine.

Monochloramine is the best solution against Legionella and other water pathogens without corrosion risks.

Why SANIKILL doesn’t create this problem?

Being a weaker oxidant if compare to other chlorine-based disinfectants, Monochloramine can be used as a disinfectant for long periods without produce any damage to the hydraulic system, regardless the material of which they are made of.

SANIKILL has shown to be suitable for the treatment of all the domestic hot water distribution systems made of copper, stainless steel, galvanized iron, polyethylene, etc. It’s the end of pipe corrosion due to disinfection. Monochloramine is material respectful.

The science behind

Chlorine is a strong oxidant and can attack pipe materials (both metals and plastic) to provoke corrosion issues. The reaction between chlorine and iron pipe is depicted below: ![]() Reaction 3: iron (II) oxidation by chlorine Boffardi (Boffardi 1992) showed that chlorine at concentrations above 0.5ppm leads to iron corrosion in drinking water piping. More recently, it has also been shown (Hassinen 2004, Castagnetti 2010) that chlorine is also corrosive on PE (polyethylene) and PP (polypropylene) pipes which are going to be more and more common for water distribution piping (particularly in Europe).

Reaction 3: iron (II) oxidation by chlorine Boffardi (Boffardi 1992) showed that chlorine at concentrations above 0.5ppm leads to iron corrosion in drinking water piping. More recently, it has also been shown (Hassinen 2004, Castagnetti 2010) that chlorine is also corrosive on PE (polyethylene) and PP (polypropylene) pipes which are going to be more and more common for water distribution piping (particularly in Europe).

Chlorine dioxide is also reported to be corrosive both on metallic and on plastic pipes (Yu 2011, 2013) and it has been shown that corrosion reaction is the principal factor responsible for chlorine dioxide consumption in building water systems (Zhang 2008).

The science behind

Iron being a micro element improving Legionella metabolism, there are evidences that corrosion products enhances the Legionella colonization in building piping systems. Eventually, the remediation of these premises piping systems becomes increasingly difficult due to the presence of the corrosion products. Monochloramine instead is shown to be less aggressive towards pipe materials (Treweek 1985, Le Chevalier 1993, McNeill 2001). Tests extensively carried out by our laboratories on different pipe materials (copper, galvanizer iron, stainless steel, PEx, PPr, C-PVC, unpublished results 2005 – 2015) show that this is actually the case.

Our 10+ years direct experience with more than 200 applications in any type of premise showed that only old NBR (natural rubber) seals, gasketsor O-rings can be possibly attacked and swelled by monochloramine at drinking water levels (up to 4 mg/l) and that EPDM is much more resistant, even in hot water. Of course, fluorinated polymers like PTFE, PFVD, PFA,… are completely resistant to both monochloramine and chlorine even at higher temperature and pressure.